In the intricate world of metallurgy, الفولاذ المقاوم للصدأ (SS) and Cold Rolled Close Annealed (CRCA) steel occupy unique positions, each with its own set of properties and applications. In this article, let’s delve into the fundamental difference between SS and CRCA, aiming to provide an accurate, professional, detailed, and authoritative comparison.

ما هو الفرق بين SS و CRCA؟

Firstly, let’s explore the composition and characteristics of SS. SS, as the acronym suggests, is a corrosion-resistant alloy of iron with a minimum of 10.5% الكروم. Depending on the specific grade, SS may also contain other elements such as nickel, molybdenum, titanium, and nitrogen, which further enhance its properties. SS is renowned for its corrosion resistance, thanks to the chromium oxide film that forms on its surface, protecting it from oxidation and corrosion. Additionally, SS exhibits excellent ductility, toughness, and weldability, making it suitable for a wide range of applications.

On the other hand, CRCA steel is a type of carbon steel that undergoes cold rolling and close annealing processes. Cold rolling involves rolling the steel at room temperature or below, which improves its surface finish, mechanical properties, and dimensional accuracy. Close annealing, on the other hand, is a heat treatment process that removes internal stresses and improves the steel’s ductility and toughness. CRCA steel is primarily composed of iron and carbon, with minor additions of other elements like manganese, phosphorus, and sulfur. Its mechanical properties, such as strength and stiffness, are significantly enhanced through the cold rolling process.

Now, let’s delve into the key difference between SS and CRCA.

The first and foremost difference lies in their corrosion resistance. SS, due to its chromium content and the formation of the protective oxide layer, exhibits excellent corrosion resistance, particularly in oxidizing environments. This makes SS a preferred choice for applications in the chemical industry, marine environments, and food processing, where exposure to corrosive agents is common. In contrast, CRCA steel, while possessing good mechanical properties, lacks the same level of corrosion resistance as SS. It may require additional coatings or treatments to protect it from corrosion in certain environments.

The second difference is in their mechanical properties. CRCA steel, through the cold rolling process, achieves high strength and stiffness, making it suitable for structural applications that require precision and durability. Its improved surface finish also enhances its aesthetic appeal. On the other hand, SS, while also possessing good mechanical properties, is more known for its ductility, toughness, and weldability. This allows SS to be easily formed and welded into complex shapes and structures, making it suitable for a wide range of manufacturing processes.

The third difference lies in their cost and availability. SS, due to its complex alloy composition and manufacturing processes, is generally more expensive than CRCA steel. However, its superior corrosion resistance and versatility justify the higher cost in many applications. CRCA steel, on the other hand, is relatively more affordable and widely available, making it a cost-effective choice for many structural and industrial applications.

Lastly, the difference between SS and CRCA also manifests in their applications. SS is widely used in industries that require high corrosion resistance, such as chemical processing, marine engineering, and medical equipment. Its ability to withstand extreme temperatures and pressures also makes it suitable for high-performance applications like heat exchangers and pressure vessels. On the other hand, CRCA steel is commonly used in the automotive industry, construction, and machinery manufacturing due to its high strength, stiffness, and precision. It is also used in the production of household appliances, office furniture, and other products that require good surface finish and dimensional accuracy.

وفي الختام

In conclusion, SS and CRCA steel are two distinct materials with unique properties and applications. SS excels in corrosion resistance and versatility, making it suitable for a wide range of high-performance applications. CRCA steel, on the other hand, offers high strength and stiffness at a more affordable cost, making it a popular choice for structural and industrial applications.

Thank you for reading our article and we hope it can help you to have a better understanding of the difference between SS and CRCA. If you are looking for stainless steel suppliers and manufacturers online now, we would advise you to visit Sino Stainless Steel.

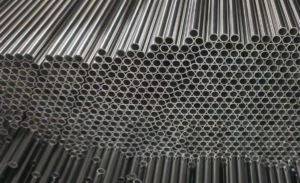

باعتبارها المورد الرئيسي لمنتجات الفولاذ المقاوم للصدأ من شنغهاي الصين، تقدم Sino المقاوم للصدأ للعملاء جودة عالية لفائف الفولاذ المقاوم للصدأ, شرائح الفولاذ المقاوم للصدأ, صفائح زخرفية من الفولاذ المقاوم للصدأ, أنابيب الفولاذ المقاوم للصدأ, أنابيب الفولاذ المقاوم للصدأ, ألواح الفولاذ المقاوم للصدأو قضبان الفولاذ المقاوم للصدأ بسعر تنافسي للغاية.

: + 86-18621535697

: + 86-18621535697  : export81@huaxia-intl.com

: export81@huaxia-intl.com